ST434 – Explosion Proof Cabinet Oven

ST434 – Explosion Proof Cabinet Oven

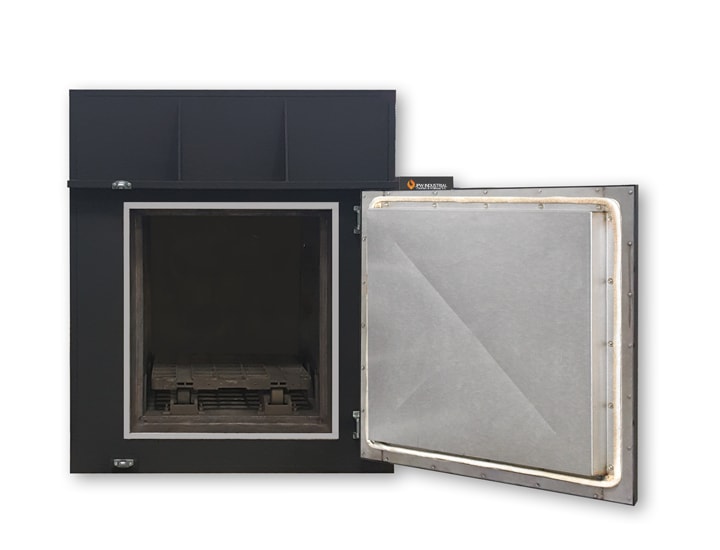

The ST434 is one of the more unique models of oven that JPW has had the privilege to manufacture. This oven was designed and manufactured for a lab in California. It is a Class 1, Division 1 – Class 2, Division 1 rated cabinet oven and will be used for munitions testing. For this reason, it was built to be explosion proof earning a NRTL certification.

Receiving NRTL certification at JPW allows the chamber to be put directly into production for the client without external certification. JPW’s ability to certify these types of ovens saves time, and money, on the client’s end, allowing for faster installation of the unit.

This special cabinet oven has a solvent rated interior and with special attention given to a non-sparking interior design. It is engineered as a low-temp unit, operating at 250F or below. Another unique feature of the ST434 is the heater control. The sheath temperatures of the heaters are controlled so the interior of the unit cannot get hotter than the flashpoint of the materials contained. This is also known as Cascade Control.

This is truly a unique cabinet oven, requiring highly important specifications and safeguards. Not only is JPW proficient in meeting such customization requests but they also maintain high quality and safety levels as the unit passes dozens of engineer reviews before delivery. This ST434 is just one of three units JPW will be engineering for their client.

JPW has the knowledge, quality and engineering skill to create a solution for your industrial oven needs. Contact us today and speak to one of our friendly and skilled engineers to get the process going.

JPW recently provided a northeastern U.S. manufacturing company with a

JPW recently provided a northeastern U.S. manufacturing company with a

This

This

This month we focus on Kevin Bailey, a specialist in industrial oven fabrication at JPW. Kevin has enjoyed working at JPW for seven years, helping make customers’ industrial oven concepts into realities.

This month we focus on Kevin Bailey, a specialist in industrial oven fabrication at JPW. Kevin has enjoyed working at JPW for seven years, helping make customers’ industrial oven concepts into realities.

This month we focus on Jerry Mitcheltree, fabrication manager and CNC programmer at JPW. Jerry has 35 years of experience working in machine programming, machine operation, mechanical design, engineering, and scheduling.

This month we focus on Jerry Mitcheltree, fabrication manager and CNC programmer at JPW. Jerry has 35 years of experience working in machine programming, machine operation, mechanical design, engineering, and scheduling.

ST434 – Explosion Proof Cabinet Oven

ST434 – Explosion Proof Cabinet Oven

The HT1322 was manufactured for a finishing supply company based out of Massachusetts. This oven features a very unique design, built with 13x2x2 ft dimensions and a vertical lift door. It is a 52 cubic foot, high-temp oven capable of reaching 850F with a temp uniformity of +/- 5 @ 800F.

The HT1322 was manufactured for a finishing supply company based out of Massachusetts. This oven features a very unique design, built with 13x2x2 ft dimensions and a vertical lift door. It is a 52 cubic foot, high-temp oven capable of reaching 850F with a temp uniformity of +/- 5 @ 800F.

This month we focus on Bryan Wack, designer at JPW. A graduate of

This month we focus on Bryan Wack, designer at JPW. A graduate of

JPW manufactured a custom HD496 cabinet oven for a distributor on the west coast.

JPW manufactured a custom HD496 cabinet oven for a distributor on the west coast.