A standard in industrial ovens, the ST333 serves in many industries like aerospace, automotive, and pharmaceutical with numerous applications like: heat treating, curing, burning, ageing, drying, life testing and more.

A standard in industrial ovens, the ST333 serves in many industries like aerospace, automotive, and pharmaceutical with numerous applications like: heat treating, curing, burning, ageing, drying, life testing and more.

The ST333 has been specially crafted by JPW Industrial Ovens & Furnaces to be thicker, stronger and more durable than competing models. Available in both low-heat and high-heat models as well as electrical or gas heating. With proper use and maintenance, the ST333 can last a lifetime.

Contact JPW today to receive more information on the ST333 or request a quote.

Two conveyors to be used for the curing of fuel and oil filters for the auto industry have been installed in Prichard, W.V. JPW Industrial Ovens & Furnaces designed the systems, one of which is gas fired and measures 60′ wide by 300 long and operates at 300°F (149°C) with a cooling zone. The other system is electric and measures 48″ wide by 144″ long and operates at 300°F with a takeaway conveyor.

Two conveyors to be used for the curing of fuel and oil filters for the auto industry have been installed in Prichard, W.V. JPW Industrial Ovens & Furnaces designed the systems, one of which is gas fired and measures 60′ wide by 300 long and operates at 300°F (149°C) with a cooling zone. The other system is electric and measures 48″ wide by 144″ long and operates at 300°F with a takeaway conveyor.

The order was delivered within 12 weeks.

*This original article was posted on the Process Heating website.

JPW Industrial Ovens & Furnaces delivered two conveyors for the curing of fuel and oil filters for the auto industry. The two systems are continuous process, one gas fired 60”wide x 300” long operating at 300F with a cooling zone, the other system is an electric 48”wide x 144” long operating at 300F with a take away conveyor system. The systems are installed in Prichard, West Virginia located in the United States.

On the details of this order, JPW mechanical engineer Bryan Wack stated, “We worked closely with the customer to develop and provide the right solution.” JPW takes pride in spending time with the customer in the inquiry stage to thoroughly understand the customer’s process so the right solution can be offered.

The order was handled direct by the factory and was delivered within a 12 week period from placement of order. The main advantages of the JPW brand are:

JPW Industrial Ovens & Furnaces designs and manufactures a large variety of ovens and furnaces for various industrial markets. Our ovens and furnaces have a wide range of temperature and can be designed in continuous or batch configurations. Please visit our website or call to inquire about your oven and furnace needs. Bring Power, Precision and Performance to your processes today.

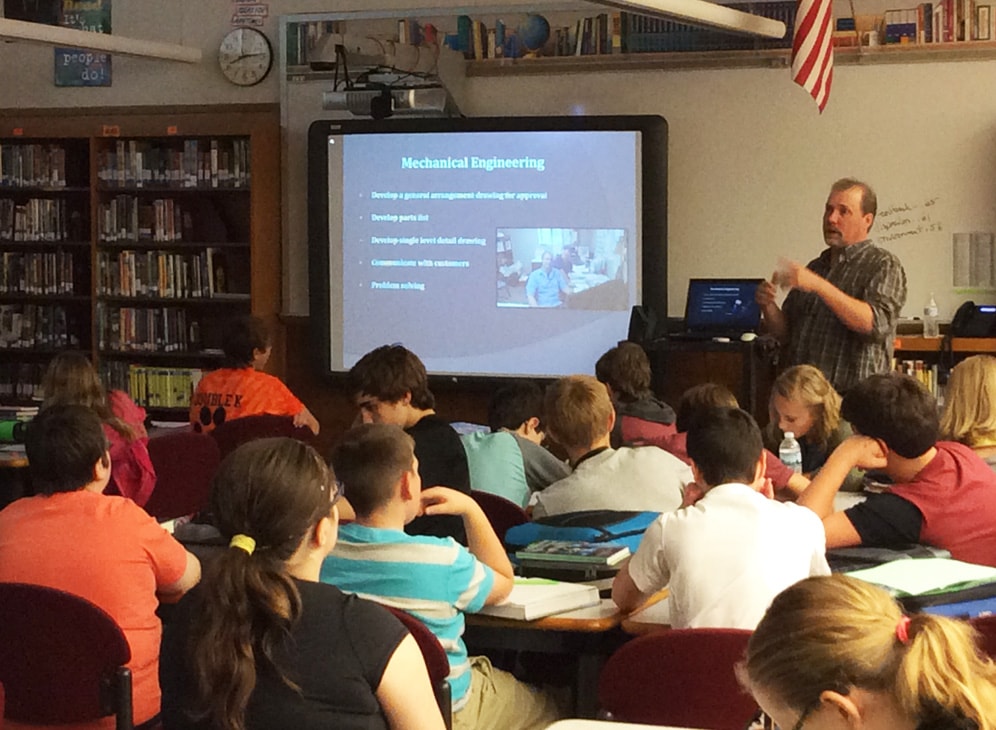

Our President Mike Jameson gave a presentation to 7 classes of 8th graders at a local school. The presentation was centered on how our business as a manufacturer has many different areas within the company and how each area works. As well as, how each area contributes to the company’s final product.

Our President Mike Jameson gave a presentation to 7 classes of 8th graders at a local school. The presentation was centered on how our business as a manufacturer has many different areas within the company and how each area works. As well as, how each area contributes to the company’s final product.

SEDA-COG recently assisted JPW Design & Manufacturing, Inc. with a PIDA Small Business First loan and a SEDA-COG ARC-RLF loan. The company expanded their manufacturing facility by 10,000 sq. ft. in Trout Run, Lycoming County and purchased an overhead crane to improve efficiency in the manufacturing facility. Woodlands Bank also assisted in this business expansion as well.

JPW Design and Manufacturing, Inc. was founded in 2004 by Mike Jameson, Mike Paternostro, and Tim Wagner. The company, which began operating in mid-2005, manufactures industrial ovens and furnaces for national and world wide sale. JPW has assembled a nationwide network of distributors (which essentially serves as an independent sales force), created a website for direct sales, and targeted potential customers through a direct mailing campaign.

In 2007, the company completed a 3,000 sq. ft. expansion project which enabled it to bring the sheet metal fabrication for its ovens in-house. Per Mr. Jameson, the company had encountered quality, pricing, and delivery time issues with its former sheet metal suppliers. Fabricating the sheet metal internally reduced purchasing and freight costs and ensures more consistent quality and shorter lead times. Integration of the sheet metal fabrication has been successfully completed.

The owners expanded the facility again in 2008 by an additional 5,200 sq. ft. to bring the electrical panel box assembly in-house (the only other outsourced piece of their manufacturing process at the time).The project also included construction of six offices and a conference room to allow for greater productivity for the sales and drafting departments.

In 2013, JPW Design and Manufacturing started doing business under JPW Industrial Ovens & Furnaces as well as changing their logo. The name and logo change was just one step taken to strengthen the brand they are establishing. Some of the other efforts taken to help establish their brand included advertising in industry specific publications, updating their website, as well as continued presence on the web.

JPW Industrial Ovens & Furnaces makes custom-made industrial ovens. Their Lab, Bench, Walk In, Cabinet and Custom-made Industrial Ovens are crafted to suit their customers’ needs. They offer design, prototyping, welding and assembly. They have over 100 years of combined experience serving industrial markets with innovative oven products, design solutions and competitive services, and they are skilled at finding solutions and crafting each oven to suit your unique needs.

The company’s dedication of excellence to their customers and the products they sell make them a leader in their field.

“Working with Seda-Cog has been very beneficial to our company to be able to expand. We really appreciated all of the knowledge and expertise Ray Haden, one of the loan agents we worked with, shared with us. Seda-Cog was able to get us a low interest loan that fit our companies needs!” – Mike Jameson, President of JPW

JPW Industrial Ovens & Furnaces has received an order for a large preheat oven to be used to preheat and remove moisture from aluminum castings. The oven was ordered by an aluminum extrusion and forging company located in the United States and will be delivered in the third quarter of 2015. The oven will have a maximum temperature rating of 750 F and will be natural gas fired. The oven load will be 40,000 lbs and have a heat up time of 2 hours. The internal size is 15’w x 6’d x 10’h with a vertical lift door.

On the details of this order, JPW electrical engineer Kim Stout stated, “It’s an exciting project and we are proud to be selected to provide the solution.” JPW takes pride in spending time with the customer in the inquiry stage to thoroughly understand the customer’s processes so the right solution can be offered.

The order inquiry was handled initially through a distribution channel that is a partner with JPW in leveraging our brand in a very mature market. The main advantages of the JPW brand are:

JPW Industrial Ovens & Furnaces designs and manufactures a large variety of ovens and furnaces for various industrial markets. Our ovens and furnaces have a wide range of temperature and can be designed in continuous or batch configurations. Please visit our website or call to inquire about your oven and furnace needs. Bring Power, Precision and Performance to your processes today.

Today, JPW Industrial Ovens & Furnaces is in the finishing stages of manufacturing a large electric high temperature vertical lift door furnace for an Aerospace company located in the United States. The temperature range of the furnace will be 200 F to 1250 F. The interior work space is 72”w x 72”h x 72”d. The uniformity specification is unique in that there will be multiple work envelopes qualified within the work space. Those specifications are +/-5 F at various operating temperatures. The unit is on track to be delivered in early May 2015.

On the details of this order, JPW Vice president of operations Mike Paternostro stated, “This is a great opportunity for JPW and our employees to show the versatility and quality of our processes and finished products.” JPW takes pride in spending time with the customer in the inquiry stage to thoroughly understand the customers processes so the right solution can be offered.

The order inquiry was handled initially through a distribution channel that is a partner with JPW in leveraging our brand in a very mature market. The main advantages of the JPW brand are:

JPW Industrial Ovens & Furnaces designs and manufactures a large variety of ovens and furnaces for various industrial markets. Our ovens and furnaces have a wide range of temperature and can be designed in continuous or batch configurations. Please visit our website or call to inquire about your oven and furnace needs. Bring Power, Precision and Performance to your processes today.