They are industrial equipment that uniformly heats or dries materials through maximum air circulation. These ovens come in various sizes and shapes. Batch ovens can be used for a range of applications, such as PVC processing, fiberizing rubber, and polymer curing. At JPW Ovens & Furnaces, we specialize in custom batch industrial ovens specifically tailored to each client’s individual needs, allowing for greater flexibility, accuracy, and control than ever before.

Overview of custom batch industrial ovens and their importance in manufacturing processes

Custom batch industrial ovens provide a practical solution for many manufacturing processes. They are designed to efficiently facilitate high-volume production and a wide variety of products. Ovens of this type also have highly flexible capabilities, allowing them to work with different materials and environments. Moreover, they offer several safety features that increase operational safety against potential hazards such as sparks, dust, and smoke. In terms of design and construction, custom batch industrial ovens are strongly built using quality components to provide maximum performance with minimum energy consumption. With all these features combined, custom batch industrial ovens can be vitally important parts of any production system – saving time, money, and resources while producing optimally safe results.

Custom batch industrial ovens provide a practical solution for many manufacturing processes. They are designed to efficiently facilitate high-volume production and a wide variety of products. Ovens of this type also have highly flexible capabilities, allowing them to work with different materials and environments. Moreover, they offer several safety features that increase operational safety against potential hazards such as sparks, dust, and smoke. In terms of design and construction, custom batch industrial ovens are strongly built using quality components to provide maximum performance with minimum energy consumption. With all these features combined, custom batch industrial ovens can be vitally important parts of any production system – saving time, money, and resources while producing optimally safe results.

Benefits of using custom batch industrial ovens in manufacturing

Custom batch industrial ovens provide several substantial benefits to manufacturing operations. They allow operators to precisely target temperatures in a variety of difficult-to-control energy sources, such as electric and gas, resulting in even heating and superior results. Custom ovens are also designed to handle the large-scale tasks needed for the most advanced industrial operations, allowing for high production rates with fewer costly stoppages due to system issues. All these advantages make custom batch industrial ovens an invaluable asset to manufacturing facilities looking for reliable options without compromising production quality or speed.

Different types of custom batch industrial ovens for various applications

Due to their unique design, these custom ovens can be configured to fit many process requirements, whether dry-heating, curing, annealing, baking, or sterilizing. Oven sizes range from small tabletop units to more extensive walk-in scale solutions, perfect for more complex processes. In addition, different heating technologies are available for each oven type – convection air circulation, in-direct or direct gas heat transfer, infrared radiation, and others – allowing users to select the best suited for their specific material and application.

Factors to consider when selecting a custom batch industrial oven

Selecting the best custom batch industrial oven for your specific production needs can be daunting. Some factors to consider are the cycle time, product throughput, type of control system, and temperature accuracy. In addition, you’ll want to ensure that your oven is flexible enough to accommodate changing production requirements and easy to use. It is also essential to select an oven that is energy efficient and meets all relevant safety regulations. With so much to consider in choosing the most suitable custom batch industrial oven for your business, it’s important to take the time to research and ask questions to make an informed decision.

If you want to learn more, contact JPW Industrial Ovens & Furnaces. We provide a wide range of custom batch industrial ovens for various applications. With nearly thirty years of experience in designing and manufacturing industrial furnaces and ovens, JPW is your trusted partner for all your heat-treating needs. Whether you’re looking for an electric conveyor furnace, a tempering oven, or a custom-designed system for an unusual application, JPW has the perfect solution for you. Contact us today to learn more about our custom batch industrial ovens and how they can benefit your business.

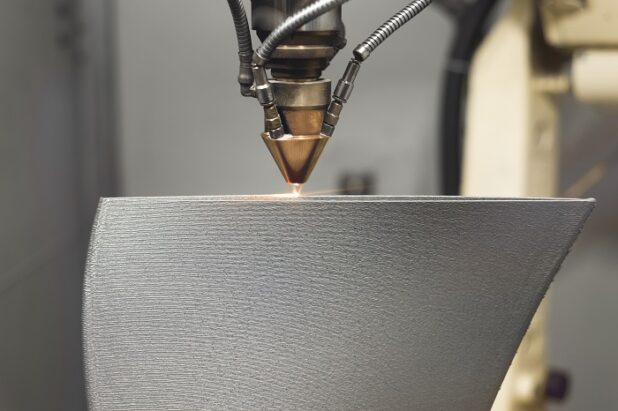

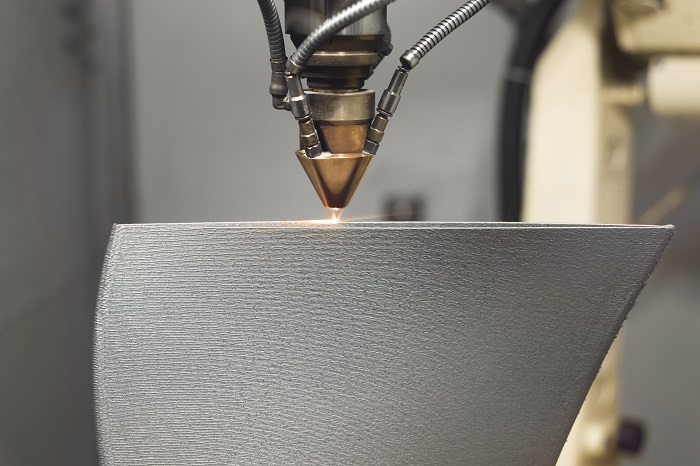

Industrial ovens are an integral part of the 3D metal printing process. The continuously evolving printing process technology starts with the creation of a 3D model or design. This digital design is then used to create a mold for the metal piece desired. Next, the mold is placed into an industrial oven, heated to very high temperatures, usually around 1,400°F (760°C). This extreme heat melts the metal, allowing it to form the desired shape as the mold dictates. Once cooled and hardened, the piece is removed from the oven and is ready for use.

Industrial ovens are an integral part of the 3D metal printing process. The continuously evolving printing process technology starts with the creation of a 3D model or design. This digital design is then used to create a mold for the metal piece desired. Next, the mold is placed into an industrial oven, heated to very high temperatures, usually around 1,400°F (760°C). This extreme heat melts the metal, allowing it to form the desired shape as the mold dictates. Once cooled and hardened, the piece is removed from the oven and is ready for use.

JPW Industrial Ovens & Furnaces provide lab and bench ovens for multiple industrial applications. Although smaller than most of our industrial ovens,

JPW Industrial Ovens & Furnaces provide lab and bench ovens for multiple industrial applications. Although smaller than most of our industrial ovens,

JPW heat-treating ovens can be used for treating a variety of metals and glass to harden or soften a material through extreme heating and cooling. Heat-treating ovens can be used to treat cylinder heads, welded and carbon steel joints, pumps or various mechanical plates.

JPW heat-treating ovens can be used for treating a variety of metals and glass to harden or soften a material through extreme heating and cooling. Heat-treating ovens can be used to treat cylinder heads, welded and carbon steel joints, pumps or various mechanical plates.

Buying a used oven isn’t always the best in the industrial oven industry. Let’s face it — when you buy a used oven, you’re usually going to settle for a model that won’t meet your exact oven specifications and will still cost you nearly full price after modifications.

Buying a used oven isn’t always the best in the industrial oven industry. Let’s face it — when you buy a used oven, you’re usually going to settle for a model that won’t meet your exact oven specifications and will still cost you nearly full price after modifications.