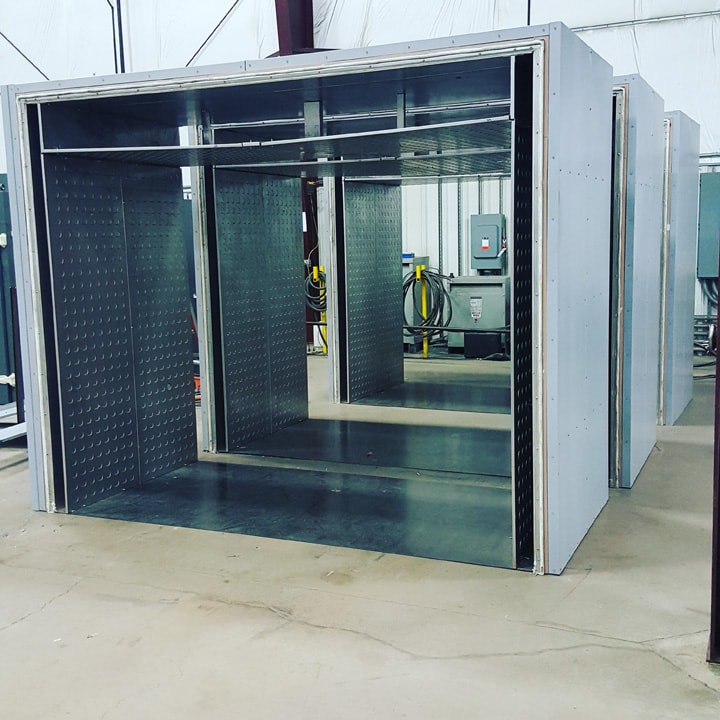

A standard in industrial ovens, the ST333 serves in many industries like aerospace, automotive, and pharmaceutical with numerous applications like: heat treating, curing, burning, ageing, drying, life testing and more. Recently, JPW has had the privilege of working with The ExOne Company to provide them with a customized version of their flagship ST333 model.

The ExOne Company specializes in providing 3D metal printing products and services, helping manufacturers to operate at reduced costs and drive innovation in the industry. JPW was commissioned by The ExOne Company to provide a customized ST333 that would allow users cure their 3D metal printed objects. Every job can require different features of an industrial oven. JPW takes this into consideration when engineering their products.

Because of the high-level of understanding and experience JPW has with industrial ovens, they are able to provide highly modified models for the specific purposes requested of by their clients. JPW is meeting the unique needs of The ExOne Company by modifying their ST333, one with a top-loading design, another with an interior rolling bed. Even the air flow direction was able to be modified to attain specific results in the curing process.

JPW Industrial Ovens & Furnaces is committed to providing high-quality cost-efficient ovens and offers a variety of customized solutions for any job.

Contact JPW today to receive more information on the ST333 or request a quote.

JPW’s line of

JPW’s line of

P is for Mike Paternostro

P is for Mike Paternostro

-min.jpg)

-min.jpg)