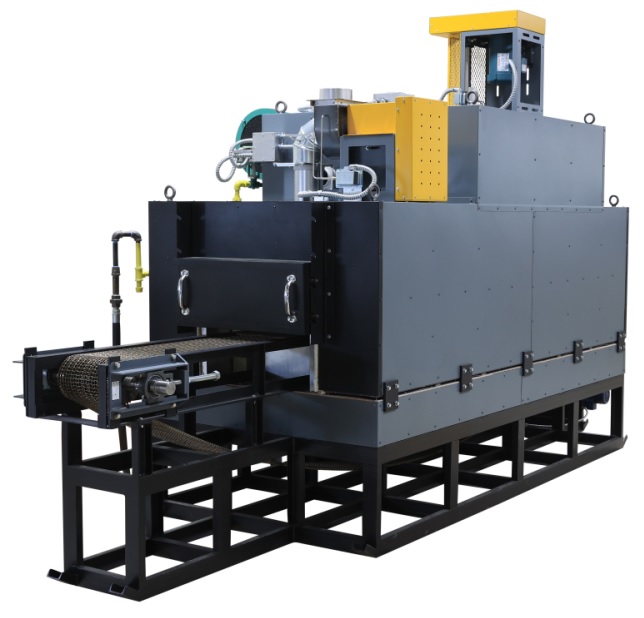

Industrial ovens stand at the heart of modern manufacturing, essential for processes from paint curing to steel tempering. In this post, we’ll explore the remarkable evolution of these crucial machines and their broad impact across various industries.

Industrial ovens stand at the heart of modern manufacturing, essential for processes from paint curing to steel tempering. In this post, we’ll explore the remarkable evolution of these crucial machines and their broad impact across various industries.

From Humble Beginnings to High-Tech Heroes

The origins of industrial ovens can be traced back thousands of years when our ancestors crafted simple chambers to dry out food and clay. These early contraptions, powered by wood or coal, were a far cry from the complex amalgamations of steel, electronics, and thermal science we see today. Over time, as metalworking and ceramics evolved, so did the need for more powerful and precise ovens.

As industrialization took hold, the requirement for consistent, high-temperature ovens surged, and engineers met the challenge head-on, employing fuel-efficient designs and the fundamentals of heat exchange to create the robust ovens needed to smelt minerals, temper metals, and fire pottery.

Applications Across the Board

The list of industries that rely on industrial ovens is as impressive as it is extensive. Here is a taste of just some of the realms these workhorses serve:

- Automotive

In the automotive industry, industrial ovens are integral to various manufacturing stages. From curing paint on vehicle bodies to shaping plastic components, industrial ovens ensure the end product meets the exacting standards of safety and aesthetics. - Aerospace

Aerospace-grade materials undergo stringent processes, such as annealing, to remove stress and hardening that occur during formation. The aerospace industry turns to industrial ovens engineered to reach and sustain temperatures that seem more at home in a celestial body than a terrestrial factory. - Electronics

From solder reflow to drying printed circuit boards (PCBs), the electronics industry leans on ovens to execute thermal procedures that are elemental in the manufacture of our array of tech gadgets.

And this is only the tip of the industrial iceberg. The textile, pharmaceutical, and energy sectors, among others, all have their own unique ovens, tailored to their specific needs and products.

Types of Ovens and their Applications

Industrial ovens might share the fundamental role of heating, yet they do so in a myriad of ways. Here are some of the most common oven types and their applications:

- Convection Ovens

The staple of many industries, convection ovens use fans to circulate hot air, ensuring uniform temperature distribution and accelerated heat transfer. They’re renowned for their consistency and speed, perfect for painted metal parts or the ferrous means of construction. - Batch Ovens

As the name suggests, batch ovens operate on a ‘one-batch-at-a-time’ principle, making them versatile and suitable for a wide range of process heating applications. Their flexibility caters to many industries’ intermittent production schedules. - Curing Ovens

Commonly found in the composites and automotive sector, curing ovens are optimized to uniformly cure and harden materials such as paint, adhesives, and coatings, often through a combination of heat and time.

Each type of industrial oven reflects the unique thermal requirements and desired production rates of its specific industrial context, speaking to the versatility and varied needs within the manufacturing world.

Future Trends in Industrial Ovens

As we constantly reinvent and reimagine the components that shape our world, the industrial ovens are no exception to innovations. Here are some trends we see turning up the heat as we look to the future:

- Smart and Connected Ovens

Like the rest of the digital world, industrial ovens are getting smarter. Integration with the Industrial Internet of Things (IIoT) allows for real-time monitoring and control, predictive maintenance, and a treasure trove of data for operational optimization. - Green Ovens

With a growing focus on sustainability, the future industrial oven will lean towards energy-efficient designs, often coupled with sustainable heating sources such as solar and waste heat recovery systems, reducing both environmental impact and operational costs. - Additive Manufacturing Ovens

The 3D printing wave has reached thermal processing. Additive manufacturing demands precise thermal controls and post-processing, driving the creation of niche ovens tailored to the unique needs of this burgeoning sector. - Customization and 3D Simulation

Oven manufacturers are starting to leverage 3D simulation tools to design custom ovens for specific customer requirements. These tools enable in-depth visualization and simulation of the heating and cooling processes, ensuring that the oven meets the desired production needs before it’s even built.

The future of industrial ovens is an exciting blend of cutting-edge technology, sustainability trends, and responsive design that addresses the most complex of heating challenges. As a result, industries can expect to see ever more efficient, effective, and environment-conscious oven solutions.

Concluding Thoughts

The story of industrial ovens is one of innovation, adapting to the ever-shifting demands of manufacturing. From its earliest beginnings as a simple heating chamber to the precision tool it is today, the industrial oven has come a long way, accompanying human progress with every step.

As we peer into the future, we find that they will continue to play a pivotal role in not just congealing raw materials into the products we love and rely on, but also heating up the sustainable, smart, and customized manufacturing landscape that our generation, and those to come, will depend on.

Hidden behind the scenes of manufacturing facilities, industrial ovens play a crucial, yet often overlooked, role in determining product quality. These unassuming appliances have a direct impact on the characteristics of many everyday items, ranging from the glossy finish of automobile parts to the flavorful crunch of our morning breakfast cereals. Often, the difference between a batch of products that meet quality standards and those that fall short can be traced back to the precision and reliability of industrial ovens.

Hidden behind the scenes of manufacturing facilities, industrial ovens play a crucial, yet often overlooked, role in determining product quality. These unassuming appliances have a direct impact on the characteristics of many everyday items, ranging from the glossy finish of automobile parts to the flavorful crunch of our morning breakfast cereals. Often, the difference between a batch of products that meet quality standards and those that fall short can be traced back to the precision and reliability of industrial ovens.

Electric boats have been gaining popularity over recent years and for a good reason. They provide an eco-friendly and cost-efficient option to get out on the water. But you may need to learn that manufacturing them requires specialized ovens to meld their parts together, making industrial ovens a key player in this green revolution. JPW Industrial Ovens & Furnaces have helped many companies develop clean energy transportation options with environmentally friendly processes throughout production – from concept to completion. In this blog post, we’ll uncover how these ovens work their magic and show why they are essential to creating electric boats.

Electric boats have been gaining popularity over recent years and for a good reason. They provide an eco-friendly and cost-efficient option to get out on the water. But you may need to learn that manufacturing them requires specialized ovens to meld their parts together, making industrial ovens a key player in this green revolution. JPW Industrial Ovens & Furnaces have helped many companies develop clean energy transportation options with environmentally friendly processes throughout production – from concept to completion. In this blog post, we’ll uncover how these ovens work their magic and show why they are essential to creating electric boats.

Clean process applications are becoming increasingly important for industries where the utmost accuracy and precision are required in production processes. Clean room ovens provide a reliable and cost-effective solution to achieve the sterile environment needed for these applications. In addition, with their wide range of features, clean room ovens offer an accessible way to ensure products meet high standards of cleanliness while reducing contamination risks.

Clean process applications are becoming increasingly important for industries where the utmost accuracy and precision are required in production processes. Clean room ovens provide a reliable and cost-effective solution to achieve the sterile environment needed for these applications. In addition, with their wide range of features, clean room ovens offer an accessible way to ensure products meet high standards of cleanliness while reducing contamination risks.