An industrial oven is a heated chamber that is used for a variety of industrial applications, including drying, curing, or baking components, parts or final products. These ovens can be used in a wide range of industries and applications, which includes aerospace, automotive, chemical processing, finishing and even electronics manufacturing.

Uses of Industrial Ovens

Industrial ovens are used for a variety of purposes depending on the industry. In the electronics industry, they’re used for drying electronic components to prevent moisture damage. In the automotive and aerospace industries, they are used for curing and heat treating various parts. Moreover, in the chemical industry, they are utilized for heating chemicals for reaction processes.

Types of Industrial Ovens

There are several types of industrial ovens available, and the choice of oven depends on the specific requirements of the task at hand.

- Batch Ovens

Also known as cabinet and walk-in ovens, are one of the most common types of industrial ovens. They are versatile and can be used for a variety of applications such as curing, drying, ageing, and annealing. - Tunnel Ovens

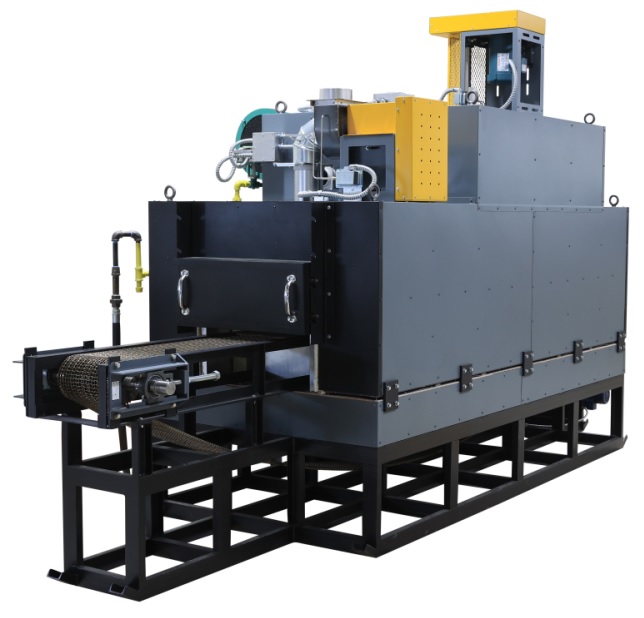

These ovens allow for continuous processing and are commonly used in industries where high volumes of a product need to be processed quickly. - Conveyor Ovens

Similar to tunnel ovens, conveyor ovens also allow for continuous processing but they use a conveyor belt to move products through the oven. - Cleanroom Ovens

These are specifically designed for industries that require a cleanroom environment like in pharmaceutical or electronic industries.

How Industrial Ovens Work

Most industrial ovens operate on the principle of thermal conduction. This heat can be generated in various ways – through gas, electricity, steam or thermal fluids.

The product to be processed is placed inside the oven and the door is closed to maintain a consistent temperature. The temperature inside the oven is then raised to the desired level, causing the material or product inside to heat up. The heat causes certain desired chemical and physical reactions to occur in the product, which could be drying, curing, or baking.

In conclusion, industrial ovens are crucial in various industries for different applications. They provide a controlled, consistent, and efficient way of applying heat to a product, and they come in various types to cater to specific industry needs. Understanding how an industrial oven works and its variety of uses allows one to appreciate the crucial role they play in our everyday lives.

JPW Industrial Ovens & Furnaces offer a comprehensive selection of high-quality, reliable, and efficient industrial ovens to meet your specific needs. Whether you require high-temperature uniformity, precise temperature control, or rapid heat-up and cool-down times, JPW’s range of ovens and furnaces can deliver. Their custom-designed solutions cater to a wide variety of industrial applications, ensuring your production processes run smoothly and efficiently. With JPW, you’re investing not just in an oven, but in the improved productivity and durability of your industrial operations.