Industrial drying ovens are integral components in various manufacturing processes that remove moisture from materials. From electronics to pharmaceuticals, these ovens play a crucial role in ensuring the quality and safety of products. This concise guide sheds light on the operational principles of industrial drying ovens, their types, key features, and best practices for their efficient use.

Their History

Industrial drying ovens, crucial in the manufacturing sector for the dehydration of materials, trace their origins back to the late 19th and early 20th centuries. This period marked a significant transition from manual labor to mechanized processes in various industries. The invention of the industrial drying oven was pivotal, primarily to accommodate the demand for mass-produced goods. These ovens were initially designed to improve the efficiency and quality of products by reducing moisture content, thereby preventing spoilage and enhancing durability. Over the years, advancements in technology and engineering have significantly evolved these ovens. Today, they incorporate precise temperature controls, uniform air distribution, and energy-efficient designs to cater to various industries.

Understanding Industrial Drying Ovens

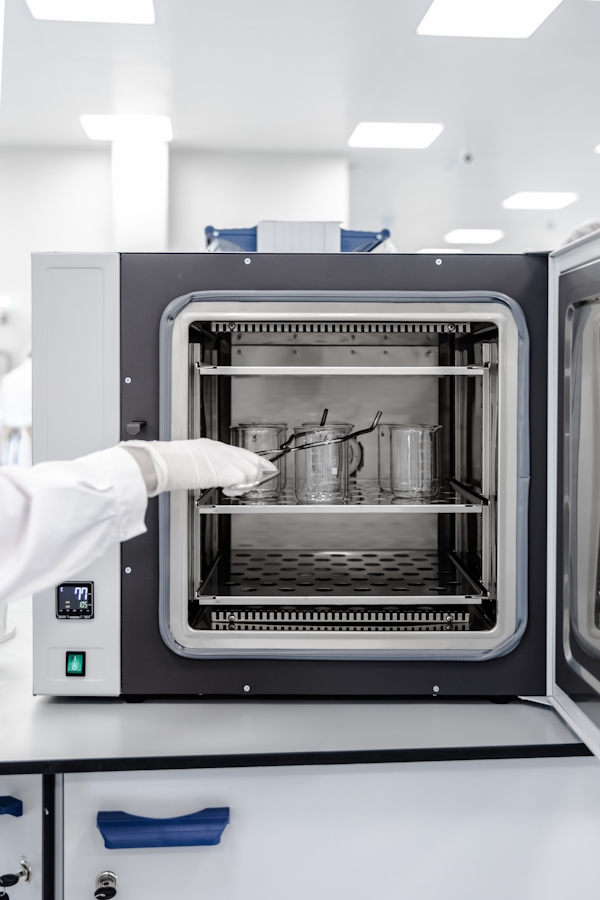

At their core, industrial drying ovens are designed to provide controlled, high-temperature environments for effectively removing water or solvents from materials. They operate on the principle of forced convection; a fan circulates hot air across the material, ensuring uniform drying. The precision in temperature control, airflow pattern, and timing distinguishes industrial drying ovens. It makes them indispensable in critical applications where moisture content must be meticulously managed.

Types of Industrial Drying Ovens

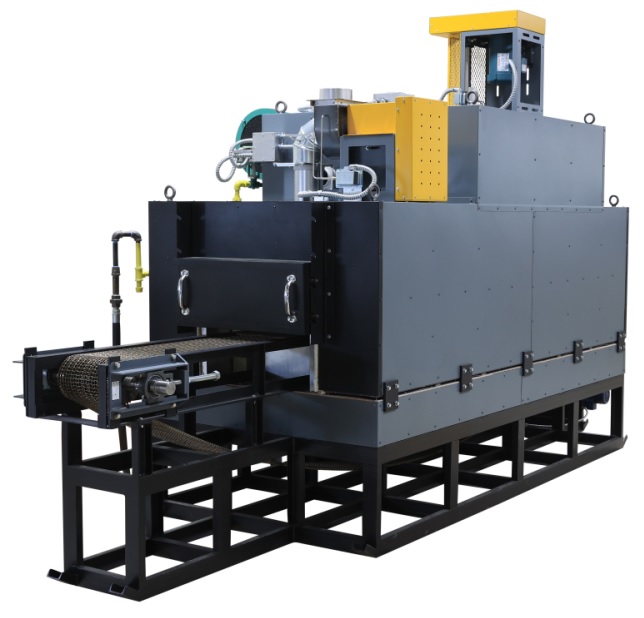

There are several types of drying ovens, each suited to specific applications based on temperature range, size, and airflow design. Batch ovens, for example, process discrete quantities of material in a single batch, which is ideal for small-scale or varied operations. Conveyor ovens, in contrast, are designed for continuous processing, where materials are fed into the oven at one end and emerge dry at the other, suitable for large-scale manufacturing.

In addition to batch and conveyor ovens, several other types of drying ovens cater to a wide range of industrial needs. Vacuum drying ovens, for instance, are vital in applications requiring the removal of moisture or solvents from heat-sensitive materials without overheating them. By reducing the pressure within the chamber, these ovens can dry materials at lower temperatures, decreasing the risk of altering or damaging the product. Another innovative variant is the rotary drying oven, designed to tumble materials within the drying chamber, ensuring uniform heat distribution and efficient moisture removal. This type of oven is especially beneficial for granular, powdery, or somewhat lump materials that need consistent drying throughout. These drying ovens offer unique benefits, making them indispensable tools in their respective application domains, from electronics manufacturing to pharmaceuticals and beyond.

Key Features to Consider

Choosing the right industrial drying oven involves understanding several critical features. Temperature uniformity and stability are paramount to ensure consistent drying. The oven’s size and capacity must match the operation’s throughput requirements. Additionally, the type of heating method (electric, gas, infrared) and the efficiency of the oven’s insulation can significantly impact operational costs.

Operating Industrial Drying Ovens Safely and Efficiently

To ensure safety and efficiency when operating industrial drying ovens, one of the fundamental practices is to conduct regular maintenance checks. These checks help identify potential issues before they escalate into significant problems, extending the oven’s lifespan and ensuring it operates efficiently. Proper operator training cannot be overstated; all personnel operating or working near the oven must be fully aware of the operational procedures, safety protocols, and emergency measures. This training should cover everything from the correct loading and unloading of the oven to understanding the control settings and interpreting warning signals. Adherence to safety standards, including those set by the National Fire Protection Association (NFPA), is mandatory to prevent fire hazards and ensure the safe operation of the equipment. Monitoring the oven’s performance is another critical aspect, as it helps in the early detection of wear or malfunction, preventing accidents and costly downtime. Implementing these practices promotes a safe working environment and enhances the efficiency and productivity of industrial drying processes.

Best Practices for Optimal Performance

To maximize the performance of a drying oven, operators should ensure that the load is distributed evenly to facilitate uniform airflow and drying. Precautions should be taken to prevent overload, leading to inefficient operation and increased energy consumption. Regular calibration and inspection of temperature controls, sensors, and ventilation systems are essential to maintain the oven’s accuracy and efficiency.

How Can JPW Help?

The demand for efficient, reliable, high-quality industrial drying ovens is critical for numerous sectors, including manufacturing, aerospace, automotive, and pharmaceuticals. Choosing the right partner for these essential components cannot be overstated. JPW Industrial Ovens and Furnaces stands out as a leader in providing solutions that meet the unique needs of each industry. With a focus on durability, precision, and energy efficiency, JPW Industrial Ovens and Furnaces ensures that your operations run smoothly and effectively, maximizing productivity and minimizing downtime.

JPW Industrial Ovens and Furnaces’ commitment to excellence extends beyond their product offerings. Our team of experts is dedicated to understanding your specific requirements and challenges, providing personalized service and support from the initial consultation to installation and beyond. Whether you need a standard drying oven or a customized solution built to specific dimensions and specifications, we have the expertise and the capacity to deliver. Choosing JPW means investing in a partnership that will help you confidently achieve your production goals, backed by quality equipment and exceptional service.

In the manufacturing world, where precision and consistency dictate success, industrial ovens have emerged as more than mere facilitators of heat processing. These ovens, from the smallest benchtop models to the largest walk-in enclosures, are the epicenter of material transformations, pivotal to the quality and properties of the products they yield. The often downplayed yet pivotal aspect of temperature uniformity profoundly impacts the final product. This blog post explores how temperature uniformity in industrial ovens becomes a keystone in maintaining high standards and producing with utmost precision.

In the manufacturing world, where precision and consistency dictate success, industrial ovens have emerged as more than mere facilitators of heat processing. These ovens, from the smallest benchtop models to the largest walk-in enclosures, are the epicenter of material transformations, pivotal to the quality and properties of the products they yield. The often downplayed yet pivotal aspect of temperature uniformity profoundly impacts the final product. This blog post explores how temperature uniformity in industrial ovens becomes a keystone in maintaining high standards and producing with utmost precision.

When ramping up your manufacturing capabilities, selecting the right industrial oven is not just a matter of preference; it’s a strategic decision that could significantly impact your production efficiency and bottom line. Suppose your business is in the market for an industrial oven. In that case, the question often arises: Should you opt for a custom-designed solution or a standard model?

When ramping up your manufacturing capabilities, selecting the right industrial oven is not just a matter of preference; it’s a strategic decision that could significantly impact your production efficiency and bottom line. Suppose your business is in the market for an industrial oven. In that case, the question often arises: Should you opt for a custom-designed solution or a standard model?

At the heart of every successful manufacturing business, where innovation meets productivity, industrial ovens play a crucial but sometimes underestimated role in driving progress. These mighty machines, often overlooked, play a pivotal role in creating products we use daily, transforming raw materials into the finished goods that propel our society forward. At JPW, we pride ourselves on crafting ovens that exceed expectations and fostering a culture of safety and longevity for your equipment. We understand that the actual value of industrial ovens extends far beyond their immediate functionality. By paying close attention to safety measures and regular maintenance, our focus isn’t solely on compliance. It’s about ensuring your operations run smoothly, safeguarding your success, and, importantly, the well-being of your team. Our commitment to excellence is unwavering as we strive to support the milestones you reach and the innovations you achieve through the reliable performance of our ovens.

At the heart of every successful manufacturing business, where innovation meets productivity, industrial ovens play a crucial but sometimes underestimated role in driving progress. These mighty machines, often overlooked, play a pivotal role in creating products we use daily, transforming raw materials into the finished goods that propel our society forward. At JPW, we pride ourselves on crafting ovens that exceed expectations and fostering a culture of safety and longevity for your equipment. We understand that the actual value of industrial ovens extends far beyond their immediate functionality. By paying close attention to safety measures and regular maintenance, our focus isn’t solely on compliance. It’s about ensuring your operations run smoothly, safeguarding your success, and, importantly, the well-being of your team. Our commitment to excellence is unwavering as we strive to support the milestones you reach and the innovations you achieve through the reliable performance of our ovens.

Industrial ovens stand at the heart of modern manufacturing, essential for processes from paint curing to steel tempering. In this post, we’ll explore the remarkable evolution of these crucial machines and their broad impact across various industries.

Industrial ovens stand at the heart of modern manufacturing, essential for processes from paint curing to steel tempering. In this post, we’ll explore the remarkable evolution of these crucial machines and their broad impact across various industries.

Hidden behind the scenes of manufacturing facilities, industrial ovens play a crucial, yet often overlooked, role in determining product quality. These unassuming appliances have a direct impact on the characteristics of many everyday items, ranging from the glossy finish of automobile parts to the flavorful crunch of our morning breakfast cereals. Often, the difference between a batch of products that meet quality standards and those that fall short can be traced back to the precision and reliability of industrial ovens.

Hidden behind the scenes of manufacturing facilities, industrial ovens play a crucial, yet often overlooked, role in determining product quality. These unassuming appliances have a direct impact on the characteristics of many everyday items, ranging from the glossy finish of automobile parts to the flavorful crunch of our morning breakfast cereals. Often, the difference between a batch of products that meet quality standards and those that fall short can be traced back to the precision and reliability of industrial ovens.

Electric boats have been gaining popularity over recent years and for a good reason. They provide an eco-friendly and cost-efficient option to get out on the water. But you may need to learn that manufacturing them requires specialized ovens to meld their parts together, making industrial ovens a key player in this green revolution. JPW Industrial Ovens & Furnaces have helped many companies develop clean energy transportation options with environmentally friendly processes throughout production – from concept to completion. In this blog post, we’ll uncover how these ovens work their magic and show why they are essential to creating electric boats.

Electric boats have been gaining popularity over recent years and for a good reason. They provide an eco-friendly and cost-efficient option to get out on the water. But you may need to learn that manufacturing them requires specialized ovens to meld their parts together, making industrial ovens a key player in this green revolution. JPW Industrial Ovens & Furnaces have helped many companies develop clean energy transportation options with environmentally friendly processes throughout production – from concept to completion. In this blog post, we’ll uncover how these ovens work their magic and show why they are essential to creating electric boats.