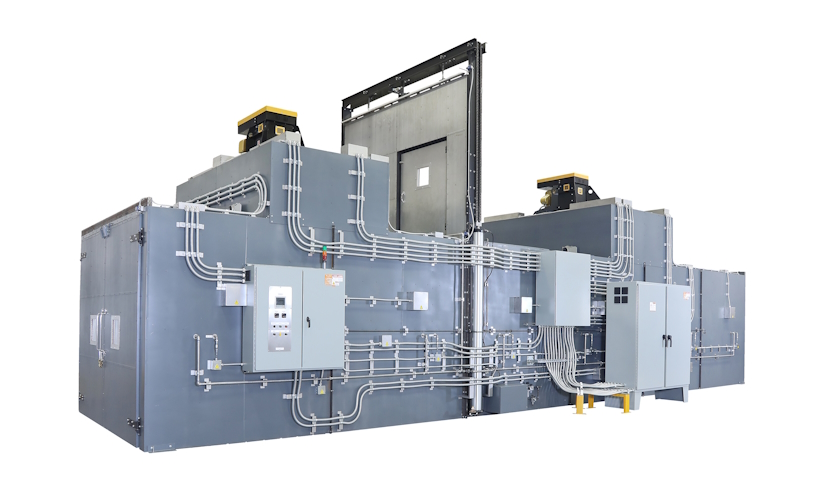

Industrial Walk-In Ovens

JPW Industrial Ovens and Furnaces not only leads but also redefines the boundaries of the industrial oven industry, offering superior walk-in oven solutions that cater to diverse applications across numerous sectors. Our expertise, cultivated over decades, empowers us to fabricate walk-in ovens that can extend up to 8,000 cubic feet, setting a benchmark for capacity and customizability in the market. This is not just a product; it’s a pivotal tool tailored to fit your specific operational requirements, no matter how unique or complex they may be. Whether it requires intricate shelving configurations, specialized racks, or carts designed for easy access by foot or vehicle, we ensure every detail is meticulously addressed.

Our ovens’ versatility is a testament to our commitment to innovation and excellence. JPW Industrial Ovens and Furnaces is proficient in serving a wide spectrum of industries, including aerospace, pharmaceuticals, automotive, and metal finishing. Our walk-in ovens are not just equipment; they are engineered marvels focused on reliability, safety, and superior energy efficiency, thereby ensuring that quality is never compromised. For organizations that demand precision—whether in airflow design, gas-fired options or require a resilient stainless-steel interior—JPW stands as the authoritative choice. We are not merely providing an oven; we are delivering a comprehensive heating solution meticulously designed to enhance your operational efficiency and elevate your output quality. Our unwavering commitment revolves around ensuring that every JPW walk-in oven seamlessly integrates into your processes, proving itself to be an invaluable asset in your production chain.

Contact us today for a quote.

Standard Features

- UL-approved 508A

- Designed to NFPA 86

- TEFC motors (totally enclosed fan cooled)- for harsh environments and long life

- Controls – all digital, microprocessor, thermocouple input temperature controller

- Circuit breakers on motor in lieu of fusing – easy troubleshooting, no fuses required for motors

- Oven on switch – Illuminated

- Heat on switch – Illuminated

- Batch Timer – shuts heat off at the end of a timed cycle on models with single set point controllers only

- SSR or SCR power controllers

- High volume recirculation blowers or fans

- Pressure differential switches

- 8lb density mineral wool board insulation

- Voltage specific (on all models 27 cuft and up only)

- Aluminized interior (on all models 27 cuft and up only, the 3.56, 5.8 and 8 cuft models have stainless interiors)

- Painted exterior

- Incoloy sheathed heating elements

- Ceramic cloth with stainless core on 650°F models

- Pressure relief latches (on 27 cuft and up models only)

Optional Features

- Forced Exhaust packages

- Gas fueled – natural or propane

- Programmable controllers (PLC)

- Recorders

- Solvent rated

- Door switch

- Shelves

- Carts

- Proportional dampers

- Inert gas purge & process

- Viewing window

- Interior light

- Stainless interior

- Stainless sealed interior

- Wall ports

- Cascade controlling (2 loops, typically one air and one product)

- Class 1, Div 2

- 24/7 timer

- Audible/visual alarm indicators

- Vertical lift door

- Custom Designs